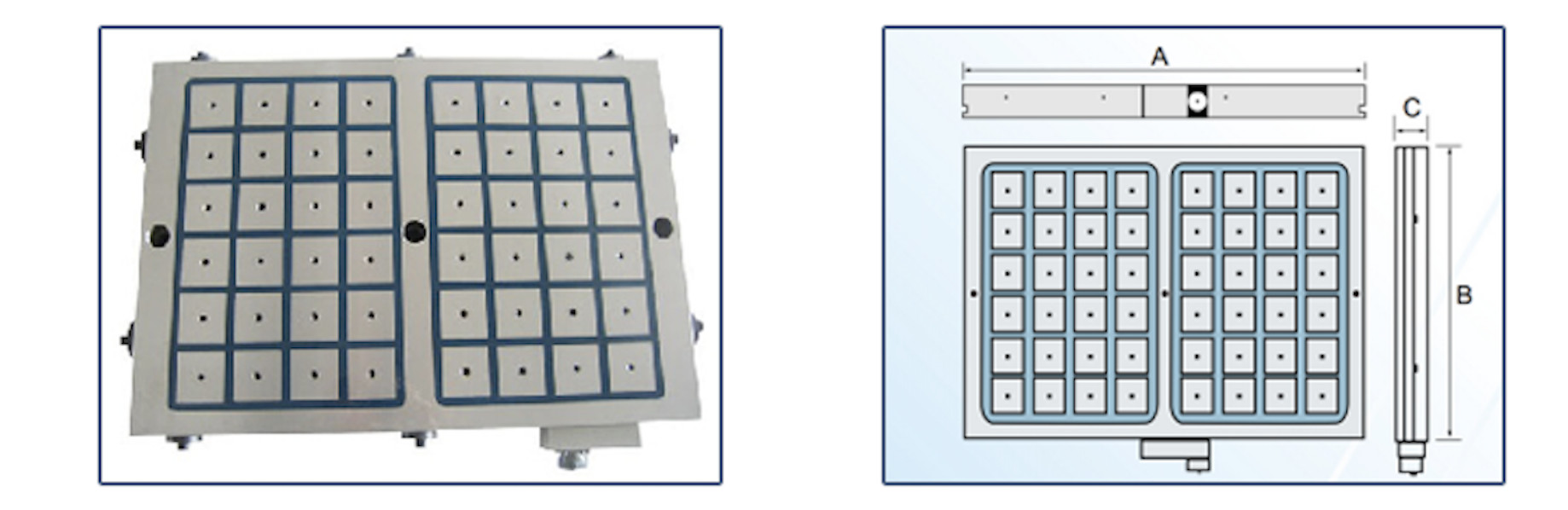

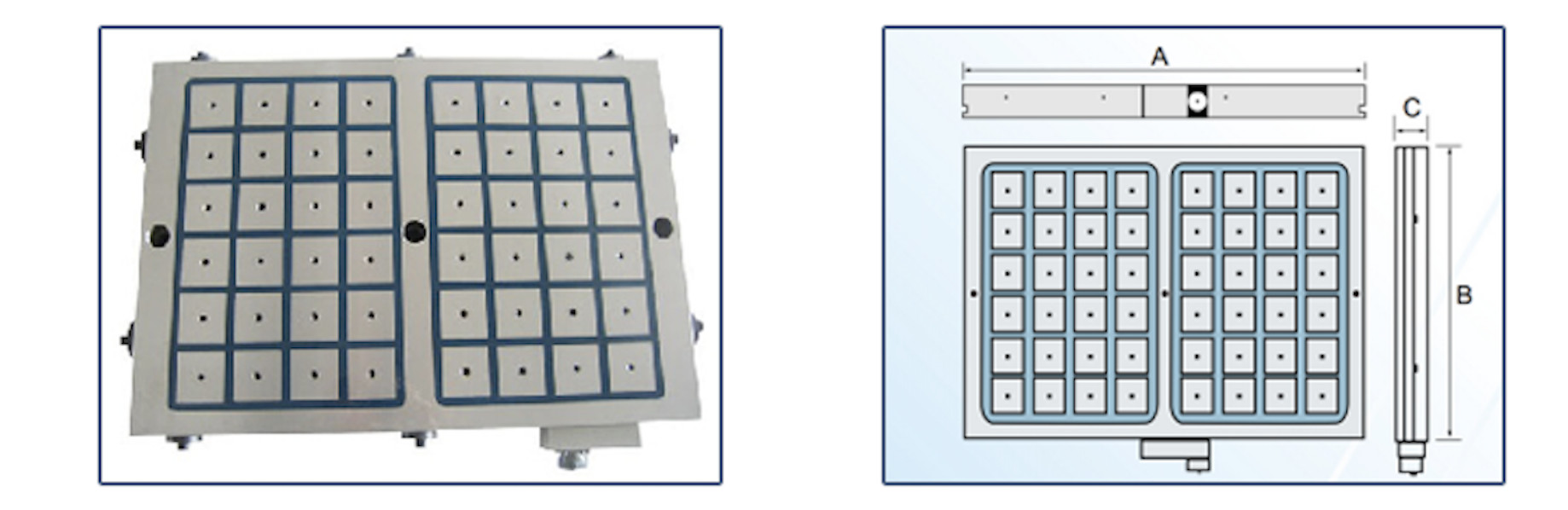

ECPMC For Quick Mold Changing System

Product Introduction

Spec sheet of electronic controlled permanet magnetic chuck for

quick mold changing system

Electric control permanent magnetic chuck for quick mold changing

system is mainly to improve the efficiency of traditional injection

molding machine, punch_x001f_ing machine, and mold clamping

machine. The system adopts the magnetization and demagnetization

action of the electronic permanent magnetic chuck to clip and

replace the mould, you can change the mould within 3 minutes. It

can either be installed in a new machine, sold as a standard

configuration to the end customer, or be retrofitted to the machine

in use, it’s both practical and convenient.

Product Parameters

| Permanent Magnetic Chuck | Electromagnetic Magnetic Chuck | Electro Permanent Magnetic Chuck |

| Magnetic Source | Ndfeb | Coil and Core | Ndfeb Anico |

| Magnetic Force Principle | Internal Magnetic Fields | Constant Current | Conversion by Electronic Control Device |

| Usage | Manual | Electric Control Device | Electric Control Device |

| Precision | About 0.02-0 05 (the Error Increased Bysizes) | About 0.01-0.02 | About 0 002-0.005 |

| Potential Risk | Prone to Security Incidents | Prone to Security Incidents | Absolute Safety |

| Magnetic Regulation | Unable to Adjust | Electric Control Device to Adjustsuction | Electric Control Device to Adjust Suction |

| Suction | Small | Medium | Large |

| Residual Magnetism | More Remanence, Demagnetiz Ation Devicerequired | Less Remanence, Demagnetizationdevice Required | Automatic Demagnetiz Ation Withoutdemagnetization Device |

| Thermal Deformation | No | Continuous Power On, Heat Generationand Thermal Deformation | No |

| Applicable Workpiece | Thin and Small Workpieces | Thin and Small, Medium Sizedworkpieces | All Kinds of Workpieces |

| Application | Mainly Used for Grinding Machine | Mainly Used for Grinding Machine | For Grinding/milling/lathe Manchine and Soon. |

| Accessories | No | Electric Control Device | Electric Control Device |

| Serive Life | 3-5 Years | 6-10 Years | 20 Years |

| Model (T) | Dimensions (MM) | Polar count | Suction (KG) |

| A | B | Thickness |

| 50 | 540 | 540 | 52 | 8 | 6000 |

| 80 | 600 | 600 | 52 | 11 | 8250 |

| 100 | 600 | 600 | 52 | 13 | 9750 |

| 125 | 660 | 690 | 52 | 15 | 11250 |

| 150 | 750 | 750 | 52 | 19 | 14250 |

| 200 | 830 | 830 | 52 | 22 | 16500 |

| 250 | 950 | 950 | 52 | 33 | 24750 |

| 300 | 950 | 950 | 52 | 33 | 24750 |

| 350 | 950 | 1050 | 52 | 44 | 33000 |

| 420 | 1100 | 1200 | 52 | 52 | 39000 |

| 500 | 1200 | 1300 | 52 | 64 | 48000 |

| 650 | 1350 | 1450 | 52 | 102 | 76500 |

| 800 | 1500 | 1600 | 52 | 118 | 88500 |

| 1000 | 1700 | 1900 | 52 | 150 | 112500 |

| 1300 | 1900 | 2200 | 52 | 201 | 150750 |

| 1500 | 2000 | 2400 | 52 | 260 | 195000 |

| 2000 | 2300 | 2600 | 52 | 329 | 246750 |

| 2300 | 2400 | 2850 | 52 | 385 | 288750 |

| 2700 | 2600 | 3050 | 52 | 454 | 340500 |

| 3200 | 2600 | 3050 | 52 | 454 | 340500 |

| 4000 | 2950 | 3300 | 52 | 641 | 480750 |

| Note: Above mentioned specification is only for one ECPMC. |

| Other specifications can be customized ,please contact us for

further information. |

X61 Introduction

X61 standard electronic controlled permanent magnetic chuck is a

new type of magnetic chuck, which useelectric pulse to control its

magnetism . No electricity is needed when X61 at work, only except

in the first1-2 seconds of magnetization and demagnetization

process. Magnetism will not lose even in the case of asudden power

cut, and the work piece will not move. X61 has the convenience of

"Electronic controlledmagnetic chuck" and the safety precision of

"Permanent magnet chuck", which is used for high precisionmilling

and grinding.

| Model | Dimensions(mm) | Polar Distance(mm) | Polar Number | Net Weight(kg) |

|

| Length | Breadth | Height | 70*70 | 50*50 |

| X61-250*250 | 250 | 250 | 68 | 70*70/50850 | 4 | 9 | 31 |

| X61-250*300 | 300 | 250 | 6 | 12 | 40 |

| X61-300*300 | 300 | 300 | 9 | 16 | 48 |

| X61-300*400 | 400 | 300 | 12 | 20 | 64 |

| X61-300*500 | 500 | 300 | 15 | 28 | 80 |

| X61-300*600 | 600 | 300 | 18 | 32 | 96 |

| X61-300*800 | 800 | 300 | 24 | 48 | 128 |

| X61- 300*1000 | 1000 | 300 | 30 | 60 | 160 |

| X61. -400*400 | 400 | 400 | 16 | 25 | 85 |

| X61-400*500 | 500 | 400 | 20 | 35 | 105 |

| X61- 400*600 | 600 | 400 | 24 | 40 | 128 |

| X61- 400*800 | 800 | 400 | 32 | 60 | 170 |

| X61- 400*1000 | 1000 | 400 | 40 | 75 | 210 |

| X61- -500*500 | 500 | 500 | 80 | 25 | 49 | 155 |

| X61- 500*600 | 600 | 500 | 30 | 56 | 188 |

| X61- 500*800 | 800 | 500 | 40 | 84 | 250 |

| X61- 500*1000 | 1000 | 500 | 50 | 105 | 310 |

| X61-600*600 | 600 | 600 | 36 | 72 | 225 |

| X61-600*800 | 800 | 600 | 48 | 96 | 300 |

| X61-600*1000 | 1000 | 600 | 60 | 120 | 375 |

| X61-600*1200 | 1200 | 600 | 72 | 144 | 450 |

| X61- -600*1500 | 1500 | 600 | 90 | 176 | 560 |

1. Cnc Flame Cutting

2. Gantry Milling

3. Cnc Processing Centor

6. Coils and Magnetic Steel Assembly

5. Deburring and Cleaning

4. Drilling Machine

7. Magnetic Steel Commissioning

8. Electrical with Stand Voltage Detection

9. Epoxy Potting

10. Suction and Pull-out Force Test

11. Surface Grinder Finish Machining

12. Surface Magnetic Remanence (inspection)

13. Finished Product Electrical with Stand Voltage Detection

14. Finished Product Appearance Inspection

15. Packing List Inspection

16. Finished Package

Other Product

Table Type Demagnetizer

Tck Frame Form Demagnetizer Electro Magnetic Lifter

Electro Magnetic Iron Remover